Description

Model | Max.Glass Size(mm) | Glass thickness(mm) | Effective intemal diameter / length(mm) | Heating Power(KW) | Capacity |

BLPL-1540 | 1500×4000 | 4-80/Glass Multilayer | 1850×4000 | 65 | 200 |

BLPL-2040 | 2000×4000 | 4-80/Glass Multilayer | 2250×4000 | 70 | 250 |

BLPL-2255 | 2200×5500 | 4-80/Glass Multilayer | 2500×5500 | 90 | 300 |

BLPL-2460 | 2440×6000 | 4-80/Glass Multilayer | 2700×6000 | 115 | 400 |

BLPL-2560 | 2500×6000 | 4-80/Glass Multilayer | 2800×6000 | 125 | 450 |

BLPL-2660 | 2650×6000 | 4-80/Glass Multilayer | 2850×6000 | 145 | 500 |

BLPL-2860 | 2850×6000 | 4-80/Glass Multilayer | 3050×6000 | 160 | 600 |

BLPL-3060 | 3000×6000 | 4-80/Glass Multilayer | 3250×6000 | 165 | 700 |

BLPL-3280 | 3250×8000 | 4-80/Glass Multilayer | 3350×6000 | 178 | 800 |

BLPL-3580 | 3500×8000 | 4-80/Glass Multilayer | 3850×8000 | 200 | 900 |

BLPL-34120 | 3400×12000 | 4-80/Glass Multilayer | 3650×12000 | 200 | 1000 |

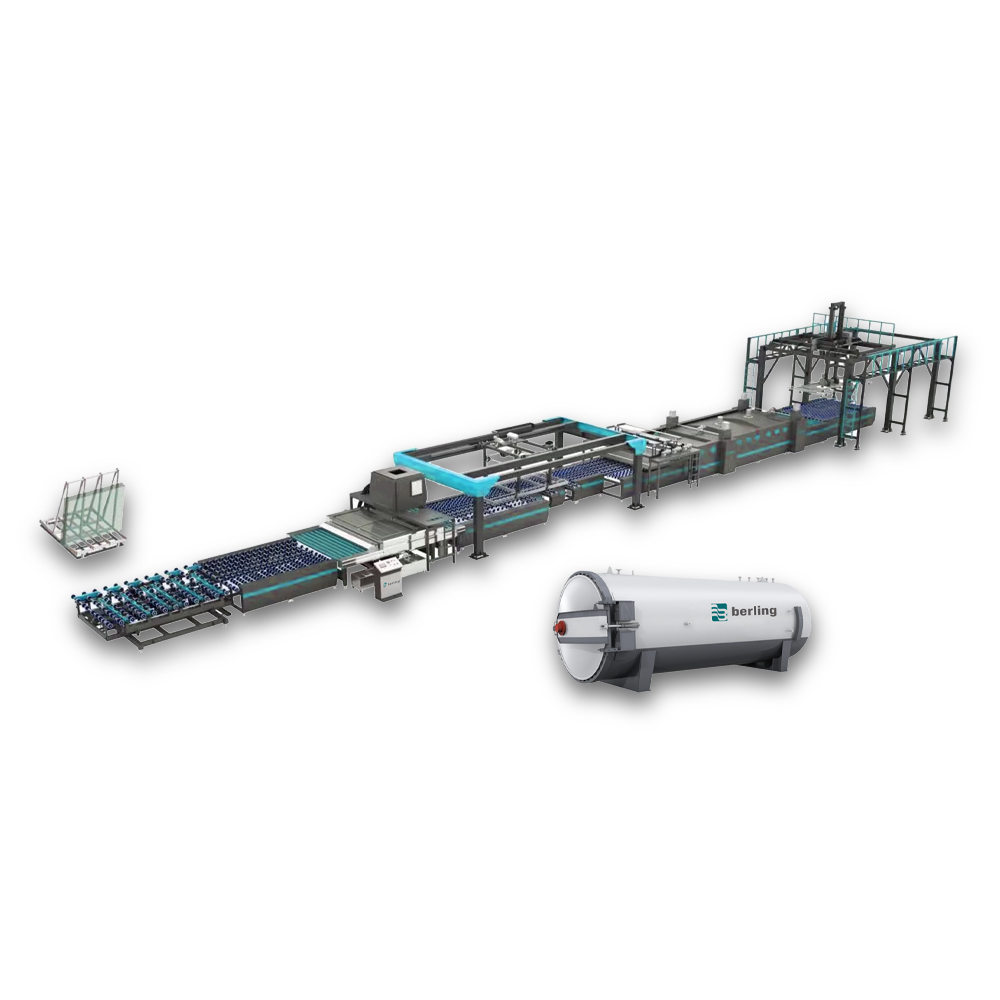

Technical characteristics of the whole laminating production line

The washing machine has a solid structure, beautiful appearance, energy-saving design, equipped with shutdown protection function, and an independent wind-supply system to make the glass more cleaner.

Glass positioning conveyor, with fast positioning speed and high precision performance, suitable for the large pieces of glass production.

Double-station glass combining machine, composed of front and rear stations, which is convenient for glass combination and film cutting, and can be operated by manually and automatically.

The suction cup of the hanger adopts special materials to ensure that no traces are left on the glass surface, so as to ensure the production of high-quality products.

The horizontal 3-roller PVB/SGP film storage machine is equipped with automatic film releasing and rolling up functions, and this design makes the film replacing work more faster and convenient.

The transition conveyor is designed with the best synchronous, smooth and fast production performance.

The structure of the roller pressing machine is reasonable, the operation is simple, the heating distribution is evenly, and the operation of the whole machine is stable and

Key Features of the PVB Laminated Glass Production Line:

Full PLC Centralized Control

All sections of the production line are integrated via a centralized PLC control system with frequency conversion and three HMI (Human-Machine Interface) stations, ensuring smooth and intuitive operation. Siemens PLC control system optionalPrecision & Stability

Critical sections are equipped with encoders and servo motors to guarantee high-precision machining and long-term equipment stability.Energy-Efficient & Eco-Friendly Design

The entire line is engineered with an emphasis on high efficiency, energy saving, noise reduction, and environmental protection.Automated Film Spreader

The film laying system features automatic film placement and electric film return. It supports up to 6 rolls of plastic film for quick replacement and user-friendly operation. PVB/TPU/SGP film optionalAdvanced Initial Pressing System

The press features a robust, easy-to-operate structure with chip room centralized control. The heating zones use domestic medium-wave infrared heating tubes, providing evenly distributed heat up to 250ºC (adjustable).Mechanical Flip-Type Unloading Table

Designed for convenient and efficient glass unloading through mechanical turnover operation.Fully Automated Autoclave System

Controlled via PLC and HMI, the autoclave ensures safe, reliable, and energy-efficient curing, optimized for high-capacity production.Intelligent Automation

Apart from operator monitoring at the loading and unloading stations, all other processes are fully automated, enabling intelligent production, reducing labor intensity, safety risks, and overall production costs.Adaptation range:Float glass laminated glass,Tempered laminated glass,Curved laminated glass,Color laminated glass,LED dimming laminated glass,Bulletproof and multi-layer laminated glass,Wired glass