Description

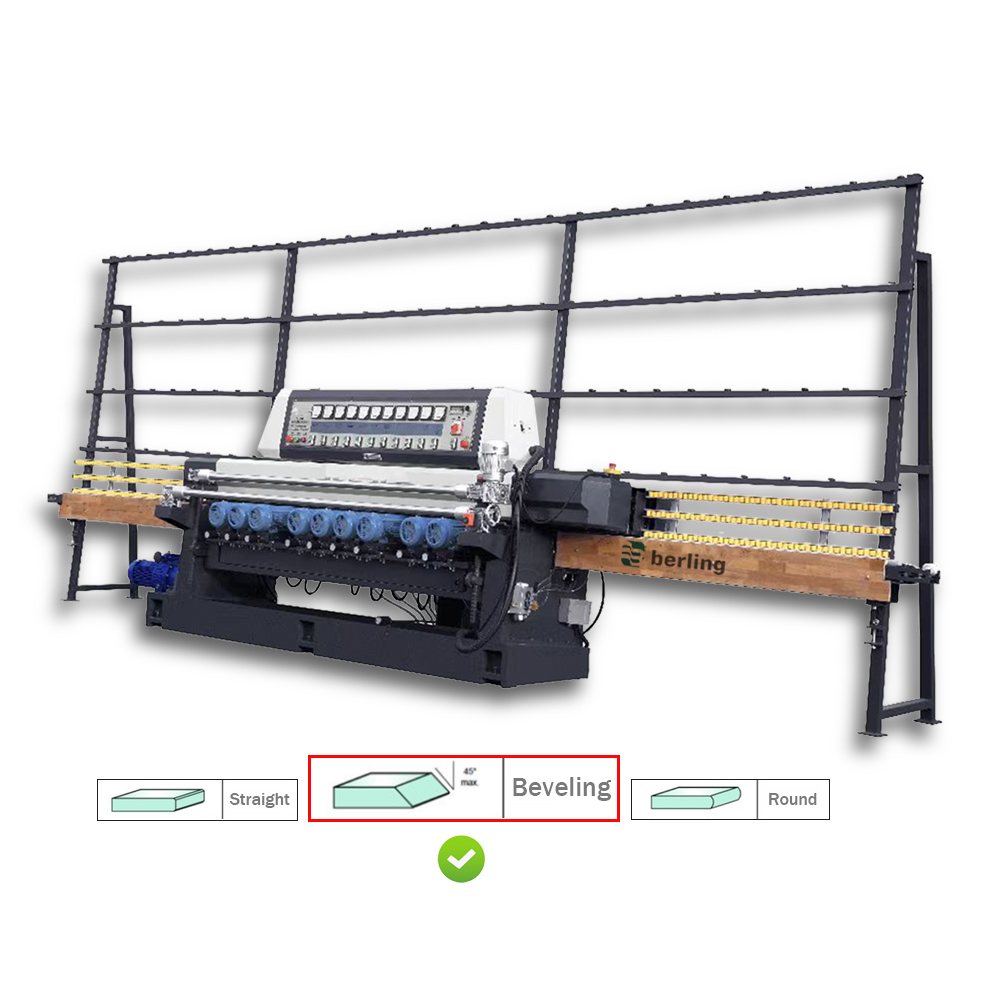

The swing drive motor allows for precise control of the swing frame angle, which can be electrically adjusted. The processing thickness is adjustable both manually and automatically, providing flexibility in operation. For ease of use, the thickness can be monitored and adjusted by referencing the thickness display.Glass edge polishing and beveling machine,2-27 Degree Beveling Machine glass processing line, the glass beveling machine is a 8/9/10/11 motors bevel and bottom grinding machine, it can complete rough grinding and fine grinding in one time, the polished effect is similar to a mirror surface, with accurate ground angles.

The base beams are all cast parts, and are processed by high-temperature annealing and precision grinders, which are durable in quality.