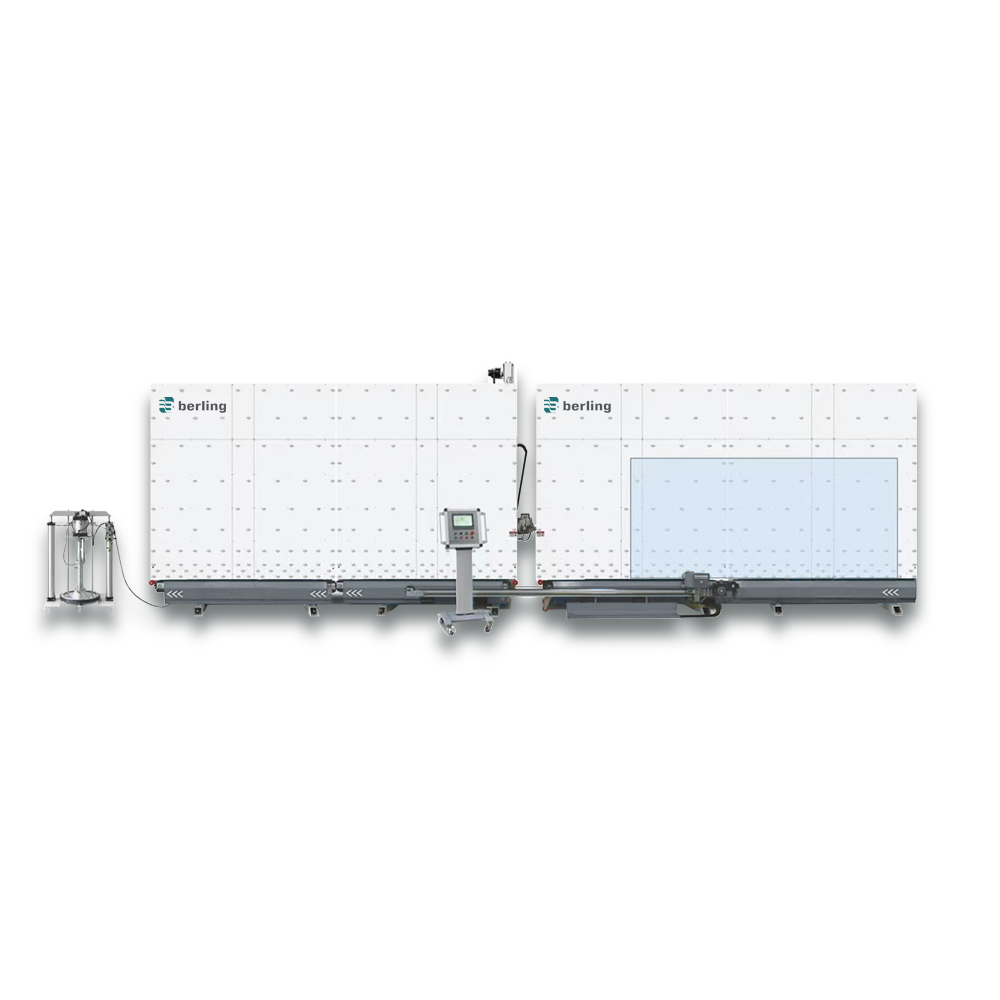

Description

Double Glazing Sealing Robot

Main feature and function:

1 this sealing line is divided into 3 parts and seal double glazing ,triple glazing

2 can keep insulating glass automatic continuously sealing, sealing with high efficiency

3 single sealant supply system(can seal silicone or polysulfide sealant)

4 adopted YASKAWA servo control system, motion controller and controller card, performance is stable.

5 glue nozzle can seal the middle of the spacer bar to make seal even and full

6 precise adjustment for the mixing ratio of the sealant.

7 can measure the depth of extruding sealant and then adjust sealing speed

| Double Glazing Sealing Machine/Sealing Robot | |||

| Product model | BL2000-32 | BL2000-42 | BL2500-42 |

| Min.glass size | 300*450mm | 300*450mm | 300*450mm |

| Max.glass size | 2000*3000mm | 2000*4000mm | 2500*5000mm |

| Glass thickness | 3-12mm | 3-12mm | 3-12mm |

| Sealant-mixing system | Single Sealant-mixing system | Single Sealant-mixing system | Double Sealant-mixing system |

| Insulating glass thickness | 12-60mm | 12-56mm | 12-56mm |

| Sealing speed | 5-30m/min | 5-30m/min | 5-30m/min |

| Sealing width | 6-24mm | 6-24mm | 6-24mm |

| Sealing depth | 2-15mm | 2-15mm | 2-15mm |

| Conveyor speed | 0-48m/min | 0-48m/min | 0-48m/min |

| Power supply | 13KW | 13KW | 13KW |

| Air supply | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Working height | 520-580mm | 520-580mm | 520-580mm |

| Dimension | 8290*2800*2950mm | 8280*2800*2950mm | 8280*2800*2950mm |

| PS | Customized size available,Choose the most suitable model according to your needs. Engineers available to service machinery overseas. | ||