Description

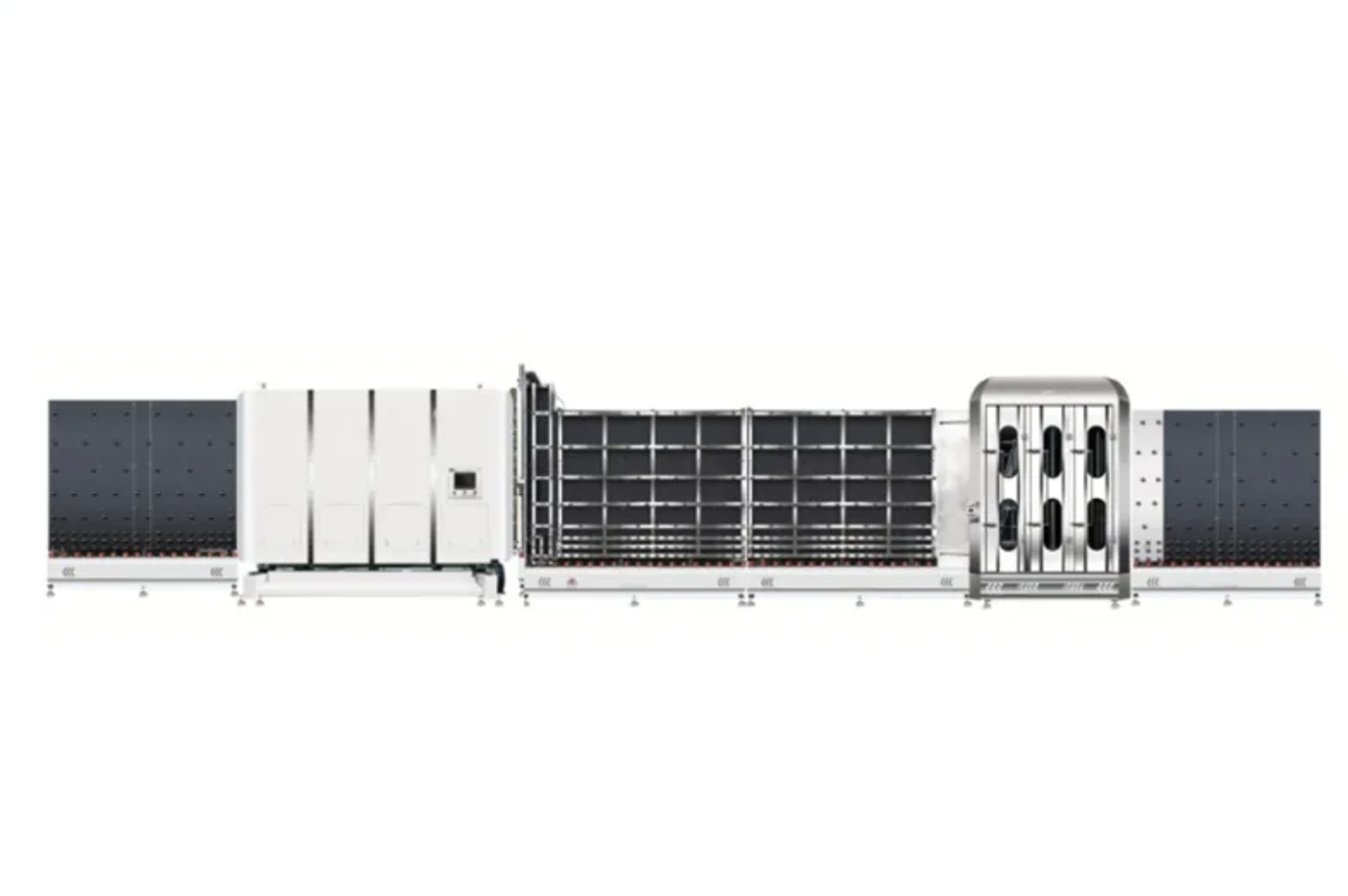

Automatic Argon Gas Filling Insulating Glass Machine carries seven or six sections: glass enter section, vertical glass washing and drying section, storage section, aluminum spacer bar and mild glass section, outdoor meeting section(option); interior flat press area with argon gasoline filling; glass output section; it can fill argon fuel extra than 90%; in the meantime can keep argon fuel

greater than 95% to decrease the waste of argon gas; It is by and large used in processing insulating glass, especially for window, door, curtain wall and so on; This double glazing glass manufacturing line has CE and ISO-9001 certification

| NO. | Power Supply | 380V 50 HZ 35KW | NO. | Name | Brand | Brand Place |

| 1 | Dimension (L x W x H) | 25410x2800x3450 | 1 | PLC | SCND | FRANCE |

| 2 | Production quantity | 600-700IG units/8hs | 2 | 10.0 inch touch screen | SCND | FRANCE |

| 3 | Max glass size | 2500mmx3500mm | 3 | Photoelectric switch | AUTONICS | KOREA |

| 4 | Min glass size | 300mmx400mm | 4 | Limit switch | AUTONICS | KOREA |

| 5 | Washing glass thickness | 3-19mm | 5 | Transducer | SCND | CHINA, FRANCE |

| 6 | Washing glass speed | 0-10m/min | 6 | Low voltage electric components | SCND | FRANCE |

| 7 | Insulating glass thickness | 60mm(can adjust) | 7 | Solenoid valve | AIRTAC | CHINA, TAIWAN |

| 8 | Transmission glass speed | 45m/min | 8 | Cylinder | AIRTAC | CHINA, TAIWAN |

| 9 | Compress air | 0.8m³/min | 9 | Liner guide rail | PMI | CHIAN, TAIWAN |

| 10 | Air pressure | 0.8Mpa | 10 | Servo motor | SIMENS / SCND | GERMANY |

| 11 | Argon gas percent | ≤95% | 11 | Transmission motor | DPG | CHINA |