Description

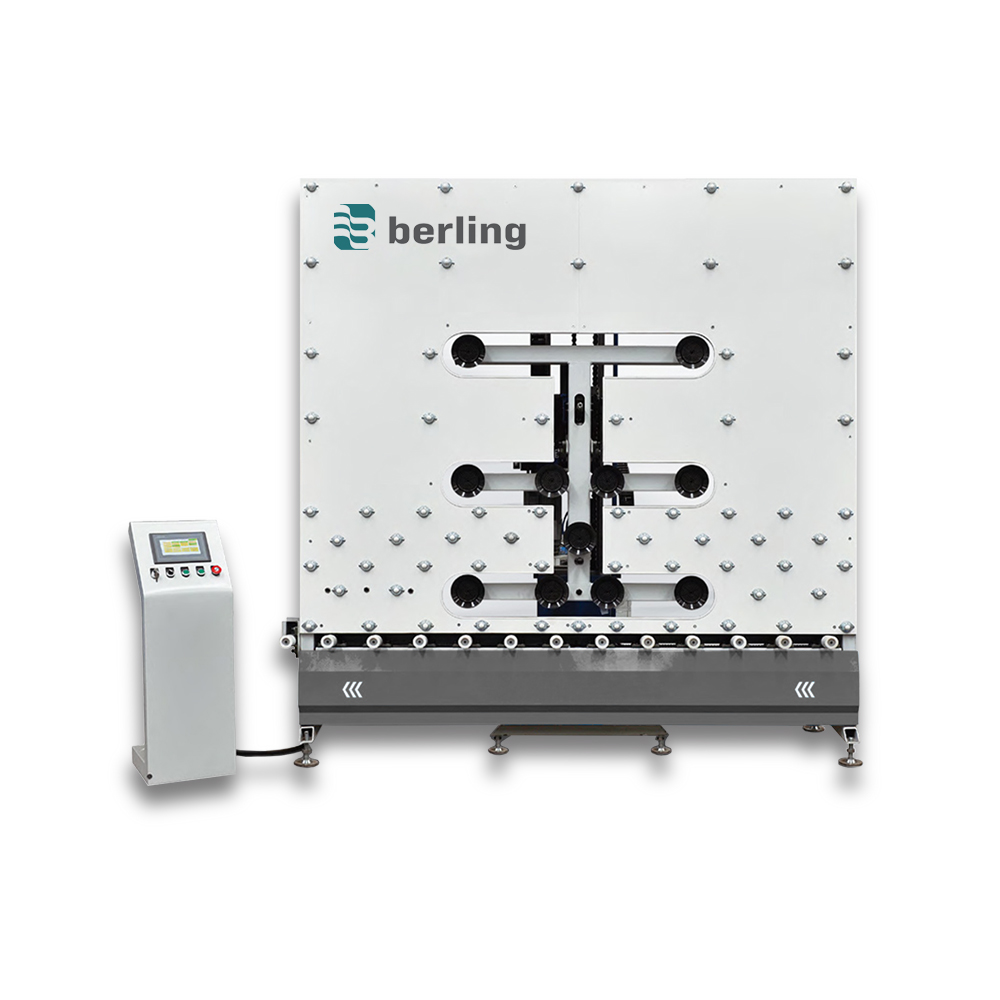

Automatic Glass Loading Machine is a patented product which is high degree of automation, saving manpower and improves production security and efficiency. This machine adopts PLC to control servo motor, photoelectric switch detects different glass size automatically. It doesn’t need to input glass size manually. It can automatic runs, sucks glass, calculates running distance. When glass shelf is empty, it will give an alarm to remind workers change it. The Automatic Glass Loading&Unloading Machine consists of a PLC control system, machine head part, transport part, suction cup structure part, and servo drive part. The transportation section automatically conveys the glass to the center position of sucker support. The servo motor drives the reduction gear by chain sprocket on the liner track to transport the glass to the sucker central position.

Main Feature:

1 it can connect with the automatic sealant line, automatic sealant sealing line date will be transfer to glass unloading machine

2 glass unloading machine can measure how many pieces glass it will put in one glass.Once glass plate is full, it will send an alarm

3 one glass plate can be added two layers to reduce space.

| Automatic IGU Glass Loading & Unloading Machine | |||

| ITEM NO. | BL2000 | BL2500 | BL2800 |

| MAX GLASS SIZE | 2000*3000MM | 2500*3500MM | 2800*4000MM |

| MIN GLASS SIZE | 400*400MM | 400*400MM | 400*400MM |

| MAX IG UNIT THICKNES | 10-50MM | 10-50MM | 10-50MM |

| PANE GLASS THICKNESS | 3-12MM | 3-16MM | 3-27MM |

| PROCESSING SPEED | 14-23 S/P | 14-23 S/P | 14-23 S/P |

| LOADING CAPACITY | 300KGS | 500KGS | 600KGS |

| PS | Customized size available,Choose the most suitable model according to your needs. | ||